01

03

<

>

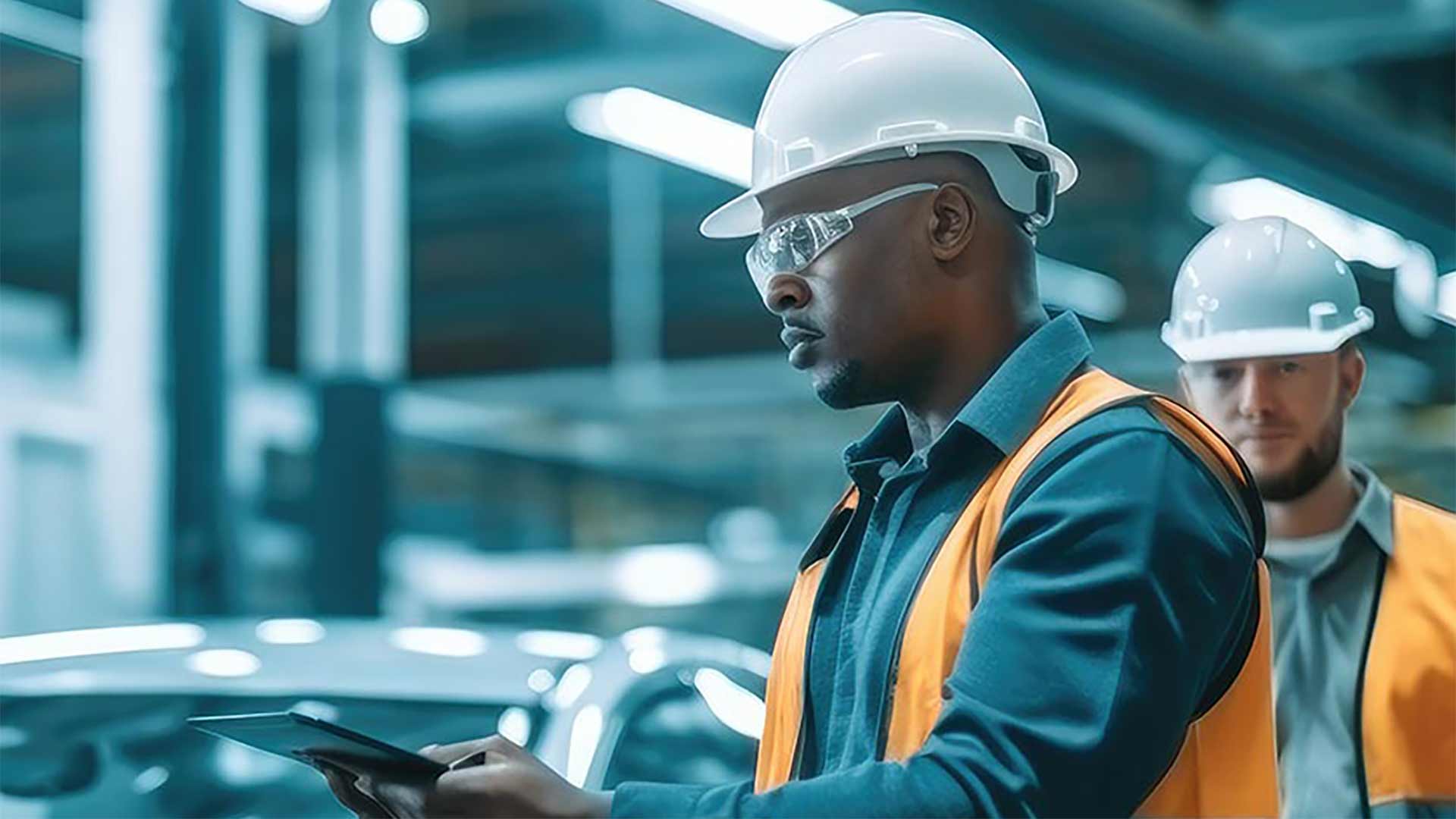

Suppliers across several industry segments – including automotive,

commercial trucks, aerospace, defense, and others.

01

03

<

>

Suppliers across several industry segments – including automotive,

commercial trucks, aerospace, defense, and others.

01

03

<

>

solutions to OEMs and Suppliers

across several industry segments

– including automotive, commercial

trucks, aerospace, defense, and others.

01

02

<

>

02

02

<

>

Vayan means quality.

Vayan means go.

Together we go faster.

We are an extension of your team delivering technology-driven,

end-to-end quality solutions that keep quality moving forward

at 5 of top 6 EV producers, 20+ OEMs, and 1,100+ suppliers.

Learn More

Vayan means quality.

Vayan means go.

Together we go faster.

We are an extension of your team delivering technology-driven,

end-to-end quality solutions that keep quality moving forward

at 5 of top 6 EV producers, 20+ OEMs, and 1,100+ suppliers.

Learn More

Vayan means quality.

Vayan means go.

Together we go faster.

We are an extension of your team delivering technology-driven,

end-to-end quality solutions that keep quality moving forward

at 5 of top 6 EV producers, 20+ OEMs, and 1,100+ suppliers.

Learn More

Vayan means quality.

Vayan means go.

Together we go faster.

We are an extension of your team delivering technology-driven,

end-to-end quality solutions that keep quality moving forward

at 5 of top 6 EV producers, 20+ OEMs, and 1,100+ suppliers.

Learn More

Vayan-At-A-Glance

0+

Full-time Employees

0+

OEMs Served

0+

Suppliers Served

0%+

U.S. EV OEMs

0+

Years in Business

0+

Projects Annually

0m+

Parts Annually

0k

Sq. Ft. of Off-Site Technical Centers

SERVICESMoving at the Speed

Moving at the Speed

of Innovation

Our services are enabling EV transformations, and we're raising the standard of quality through world-class processes, technology, and accountability.

INSPECTION, CONTAINMENT & REWORK

FINISHED VEHICLE REPAIR & REMEDIATION

BATTERY TEARDOWN, TESTING & STORAGE

ENGINEERING SUPPORT & SUPPLIER DEVELOPMENT

OFF-SITE TECHNICAL CENTERS OF EXCELLENCE

Explore our Services

SERVICESMoving at the Speed

Moving at the Speed

of Innovation

Our services are enabling the EV and sustainability transformation, and we're raising the standard of quality through world-class processes, technology, and accountability.

INSPECTION & CONTAINMENT

FINISHED VEHICLE REPAIR & REMEDIATION

BATTERY TEARDOWN, TESTING & STORAGE

ENGINEERING SUPPORT & SUPPLIER DEVELOPMENT

WAREHOUSING & LOGISTICS

FINISHED VEHICLE REPAIR & REMEDIATION

BATTERY TEARDOWN, TESTING & STORAGE

ENGINEERING SUPPORT & SUPPLIER DEVELOPMENT

WAREHOUSING & LOGISTICS

Explore our Services

SERVICESMoving at the Speed

Moving at the Speed

of Innovation

Our services are enabling EV transformations, and we're raising the standard of quality through world-class processes, technology, and accountability.

INSPECTION, CONTAINMENT

& REWORK

FINISHED VEHICLE REPAIR & REMEDIATION

BATTERY TEARDOWN, TESTING

& STORAGE

ENGINEERING SUPPORT & SUPPLIER DEVELOPMENT

OFF-SITE TECHNICAL CENTERS OF EXCELLENCE

Explore our Services

TECHNOLOGYPropelled by

Propelled by

Technology

Our leading technology and data analytics brings quality intelligence to operations - full visibility to quality performance and cost data in real-time – to give you the insights to improve productivity and decision-making.

Explore our Technology

TECHNOLOGYPropelled by

Propelled by

Technology

Our leading technology and data analytics brings quality intelligence to operations - full visibility to quality performance and cost data in real-time – to give you the insights to improve productivity and decision-making.

Explore our Technology

TESTIMONIALS

“Our relationship with Vayan has been very positive. They have met the needs of every project on every occasion and will continue to be our provider of choice moving forward.”

Major Auto Manufacturer

Quality Superintendent,

01

04

<

>

Major Tier 1 Supplier

Senior Engineer Customer Quality Support,

“Vayan’s work ethic is refreshing, especially in these times! They are always on time, work every minute, make no mistakes, and take on additional tasks without being asked. The Vayan Inspection team is an invaluable asset to our company!”

02

04

<

>

“I’ve used many third-party providers in the past, but none are like Vayan. I recommend all manufacturing suppliers to work with Vayan for a professional quality experience.”

Quality Manager,

Major Tier 1 Supplier

03

04

<

>

“We worked with Vayan in Fort Wayne, Indiana and their Operations team was excellent. Vayan is always professional and the data is second to none!”

ECG CSE,

Major Tech Company

04

04

<

>

TESTIMONIALS

“Our relationship with Vayan has been very positive. They have met the needs of every project on every occasion and will continue to be our provider of choice moving forward.”

Quality Superintendent,

Major Auto Manufacturer

>

<

01

04

>

<

02

04

“Vayan’s work ethic is refreshing, especially in these times! They are always on time, work every minute, make no mistakes, and take on additional tasks without being asked. The Vayan Inspection team is an invaluable asset to our company!”

Senior Engineer Customer Quality Support,

Major Tier 1 Supplier

>

<

03

04

“I’ve used many third-party providers in the past, but none are like Vayan. I recommend all manufacturing suppliers to work with Vayan for a professional quality experience.”

Quality Manager,

Major Tier 1 Supplier

>

<

04

04

“We worked with Vayan in Fort Wayne, Indiana and their Operations team was excellent. Vayan is always professional and the data is 2nd to none!”

ECG CSE,

Major Tech Company

OUR CUSTOMERS

Let's Move.

From quality inspection to yard management, finished vehicle repair, battery services and more, contact us today and let’s keep quality moving forward!

Contact Us

Let’s move.

From quality inspection to yard management, finished vehicle repair, battery services and more, contact us today and let’s keep quality moving forward!

Contact Us

Let’s move.

From quality inspection to yard management, finished vehicle repair, battery services and more, contact us today and let’s keep quality moving forward!

Contact Us